Invitation Letter for Drillstar Exhibition

发布时间:2025-08-07 文章来源:本站原创 阅读量:145

Dear partners, customers, and friends from all walks of life,

Hello!

Drillstar sincerely invites you to visit our two important exhibitions in 2025 to explore cutting-edge technologies and innovative products in the cutting field.

一、Event Details:

Exhibition Center: Messegelände, 30521 Hannover, Germany

Booth Number:Hall 3, Stand A14

Date & Time: 22-26 September 2025

二、Event Details:

Exhibition Center: Abu Dhabi National Exhibition Center (ADNEC)

Booth Number:16138-C

Date & Time: 3-6 November 2025

Drillstar will showcase a series of advanced machine tools and cutting tools, including:

Machine Tools

- Broaching Machine: It uses broaches to process through holes, planes, and formed surfaces of workpieces, featuring high precision and efficiency. Suitable for mass production, it can meet the precision processing requirements of components in various industries.

- Deep Hole Drilling Machine: It uses technologies such as gun drilling and BTA drilling to process deep hole systems with a length-to-diameter ratio greater than 10 and precision shallow holes. It boasts high precision, efficiency, and consistency, enabling precise processing with a single pass and capable of handling various complex deep holes.

- Gantry Machining Center: It has strong processing capabilities and is suitable for multiple processes such as milling, boring, and drilling of large components. It can ensure the processing precision and surface quality of large workpieces, playing a significant role in fields such as aerospace and shipbuilding.

- Boring Machine: It specializes in the precision processing of workpiece holes, ensuring the dimensional accuracy, shape accuracy, and positional accuracy of the holes. It is a key equipment in industries such as machinery manufacturing and automobile manufacturing.

Deep Hole Cutting Tools

- BTA Deep Hole Drill: It is an internal chip evacuation deep hole drill. The cutting fluid is fed through the gap between the drill pipe and the hole wall, and the chips are discharged from the inner hole of the drill pipe by the pressure of the cutting fluid. The blades are in a double-sided staggered tooth shape with guide blocks, which provide good guidance and prevent deflection. The deep holes drilled have excellent straightness, with processing accuracy reaching IT7-IT10 and surface roughness Ra3.2-1.6μm, widely used in aerospace, automobile industry and other fields.

- Indexable Gun Drill: Designed specifically for deep hole processing, it consists of a shank and replaceable cemented carbide inserts, with the inserts fixed by screws for convenient replacement without grinding. It has advantages such as high precision (ensuring straightness and parallelism of deep holes), high wear resistance (high-quality materials + special coating), and efficient chip evacuation (optimized insert shape + cooling system).

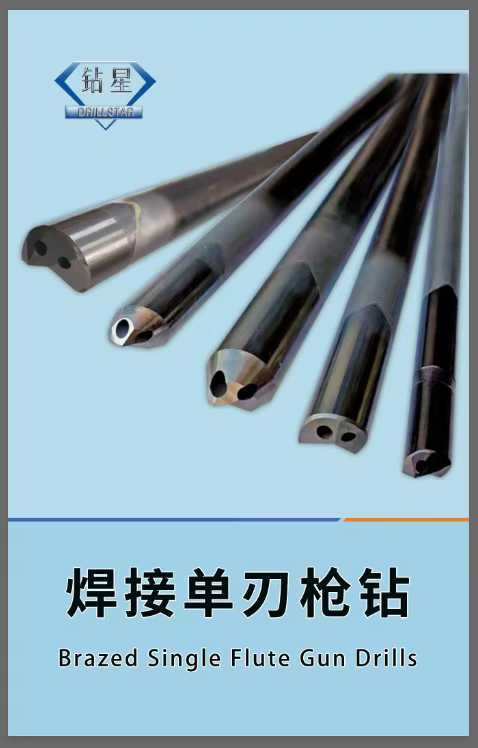

- Welded Gun Drill: The drill tip, drill pipe, and drill shank are welded into an integral structure. The drill bit is mostly made of solid cemented carbide. After the bit part is brazed with the heat-treated drill pipe, it is brazed with the precision-ground steel drill shank. It features high hole processing accuracy, good economy, and stable cutting performance, can be regrinded multiple times, supports customized length, and is suitable for gun drill machines, machining centers, etc. The double-edged type is suitable for easy-to-break chip materials (such as cast iron).

- Solid Carbide Gun Drill: Made of high-quality cemented carbide, it has high hardness, heat resistance, and wear resistance, suitable for deep hole drilling of difficult-to-machine materials such as stainless steel and titanium alloys. It reduces cutting force and vibration through optimized edge design, improving processing efficiency and surface finish; special coating enhances wear resistance and prolongs service life. Strict manufacturing tolerances ensure processing consistency, widely used in aerospace, automobile manufacturing and other fields.

We sincerely look forward to your visit to Drillstar' booth to have in-depth exchanges with our professional team, explore industry trends, and seek cooperation opportunities. We believe that face-to-face communication will enable you to gain a deeper understanding of Drillstar' products and technologies, providing strong support for your business development.Looking forward to meeting you at the exhibitions!