Drillstar participate Moscow Exhibition2025.5.26-5.29(53A16)

发布时间:2025-05-26 文章来源:本站原创 阅读量:292

2025年5月26 - 29日,Drillstar, with its deep hole drilling machines, honing machines, lathes, gun drilling machines, boring machines, drilling and boring machines, and lathes, shines at the Moscow International Machine Tool Exhibition in Russia with excellent performance and innovative technology, opening a feast for the exchange of deep hole machining technology.

Exhibition name:2025 Russia Moscow International Machine Tool Exhibition METALLOOBRABOTKA

Exhibition time:2025 .5.26—5.29

Place:Moscow EXPOCENTRE International Exhibition Center

Drillstar Booth Number:53A13

Deep hole drilling machine is the star product of Drillstar. It can drill deep hole systems and precision shallow holes with a length to diameter ratio greater than 10, achieving precise machining results with just one cutting. The processed holes have precise positions, good dimensional accuracy, high straightness and coaxiality, excellent surface smoothness and repeatability, with a minimum drilling diameter of 0.7mm. They can also overcome special deep hole processing problems such as cross holes and oblique holes.

Honing machines are used for precision machining of hole diameters, using honing heads to precisely machine the holes of workpieces, in order to improve the dimensional accuracy, geometric accuracy, and surface roughness of the holes. The fully hydraulic transmission ensures stable performance, easy operation, and high efficiency. The cylindricity can be controlled within 0.03mm, and the surface roughness can reach 0.4. The honing range is from a diameter of 40mm to 450mm, and the honing length is from 1000mm to 5000mm.

Pulling machine is suitable for processing column materials, fixing workpieces, rotating tool feed, and using external chip cutting method. The inner hole diameter for processing is between 5mm and 30mm, with a maximum hole depth of 2000mm. The maximum outer diameter range of the processed workpiece is within 60mm. The KND system is used, and the precision of the processed hole diameter is IT7-IT11.

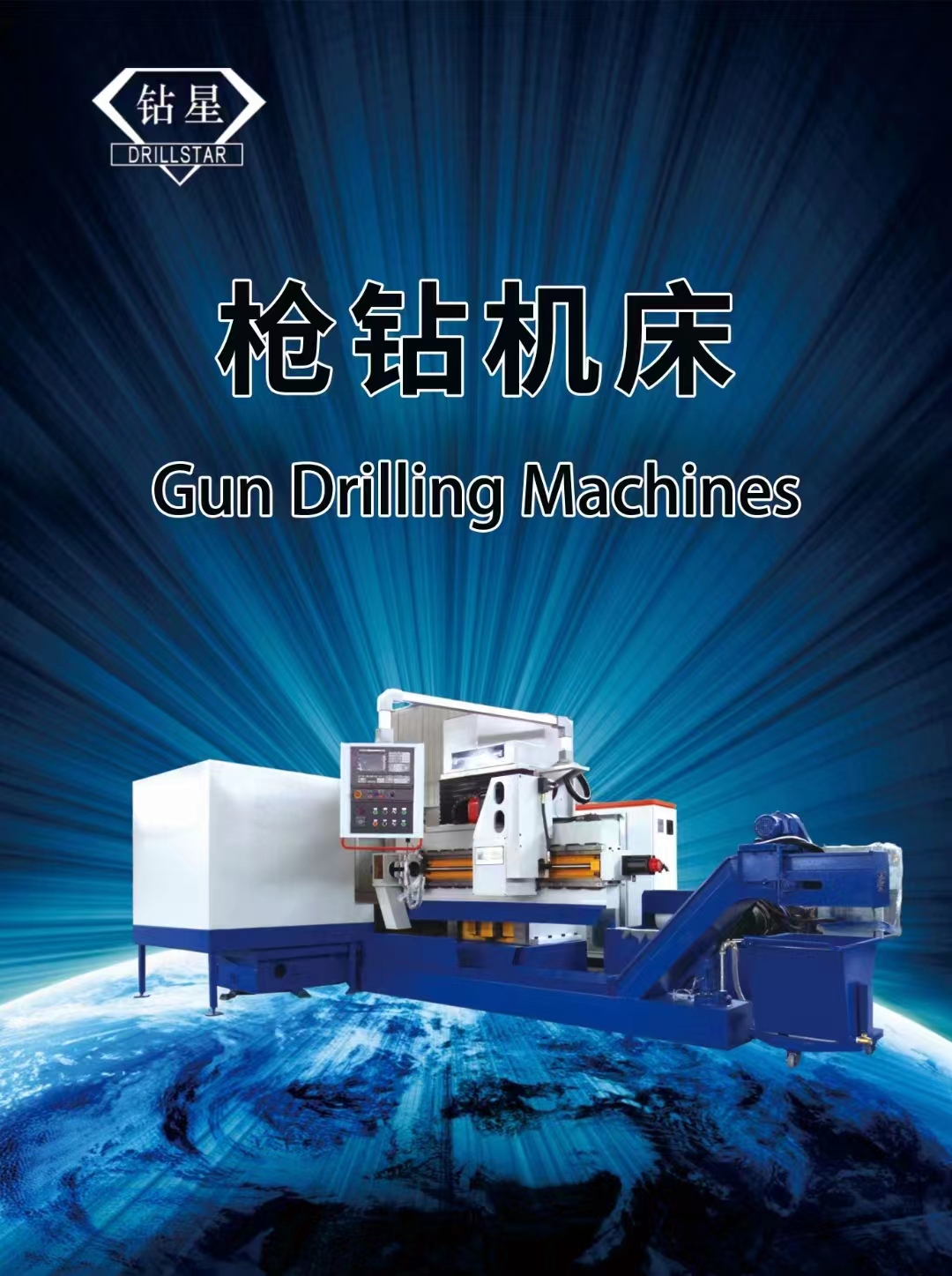

The gun drill machine is composed of multiple parts such as the bed body and spindle box, and uses a specially designed gun drill bit to perform deep hole drilling using external chip removal technology. The processing range is wide, ensuring the dimensional accuracy, positional accuracy, and straightness of holes. It is suitable for deep hole processing of materials such as steel, cast iron, and non-ferrous metals, and is widely used in industries such as molds, automotive parts, and mining machinery.

The boring machine adopts advanced boring technology and has a high-precision boring bar support and guidance system, ensuring strict control of aperture tolerance and straightness during deep hole machining, effectively avoiding problems such as out of roundness and taper of the hole wall. Paired with a precise cooling and lubrication system, it can promptly remove cutting heat, reduce tool wear, and ensure machining quality and efficiency.

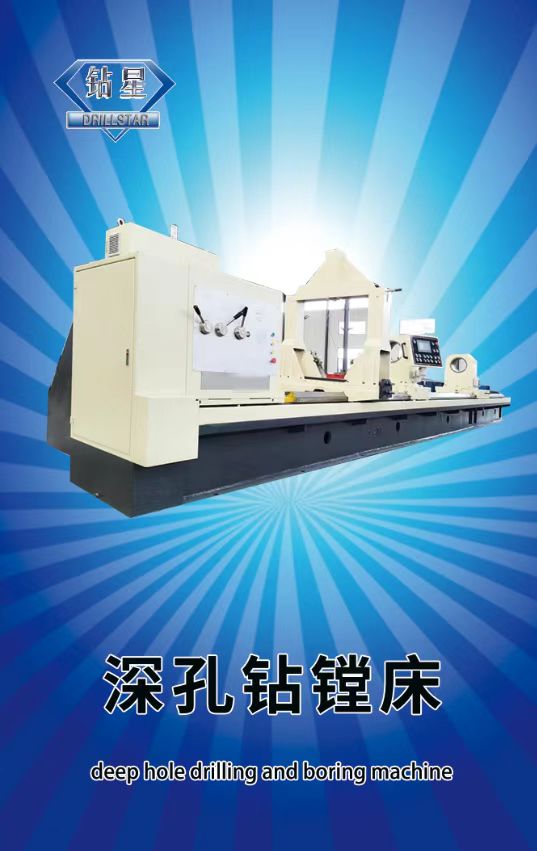

The drilling and boring machine combines the functions of both drilling and boring machines, capable of drilling and boring holes, suitable for various machining scenarios, providing more convenience and flexibility for mechanical machining, improving machining accuracy and efficiency, and meeting the diverse needs of different customers.

The lathe performance of the drilling star tool is stable and the accuracy is reliable. A spindle with high speed and precision can ensure the stability of the workpiece during rotation. The feed system precisely controls the movement of the cutting tool, enabling turning of various complex shapes and suitable for machining workpieces of various materials.

On the first day of its launch, Drillstar received numerous inquiries and negotiations from potential customers, and had in-depth technical and business exchanges with clients from Russia, Europe, and other regions. In the future, Drillstar will continue to showcase cutting-edge technology and high-quality products at exhibitions, promoting the development of the deep hole machining industry.