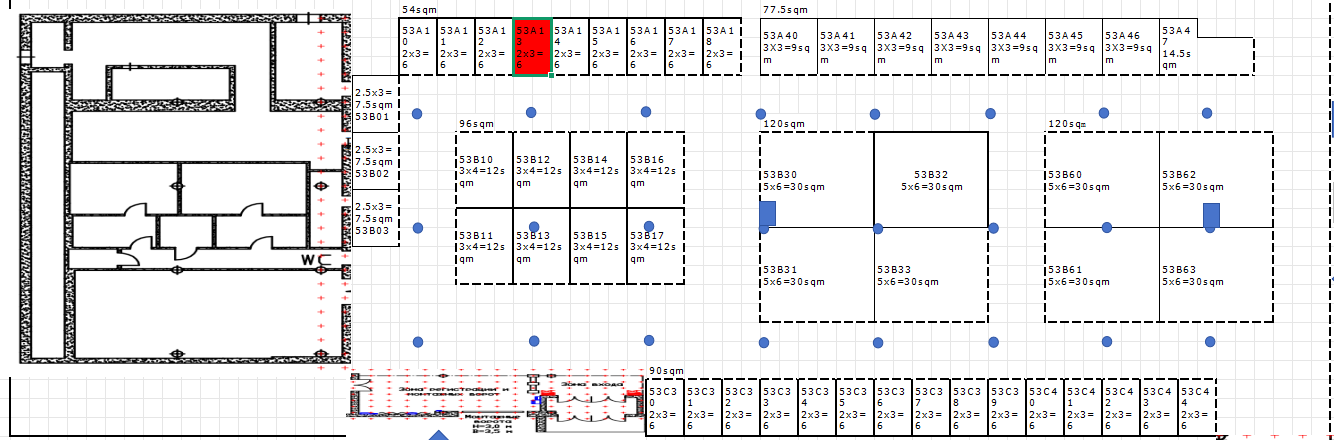

2025.5.26-5.29Drillstar will participate Moscow Exhibition(Drillstar Booth Number53A13)

发布时间:2025-04-14 文章来源:本站原创 阅读量:208

Exhibition name:2025 Russia Moscow International Machine Tool Exhibition METALLOOBRABOTKA

Exhibition time:2025 .5.26—5.29

Place:Moscow EXPOCENTRE International Exhibition Center

Drillstar Booth Number:53A13

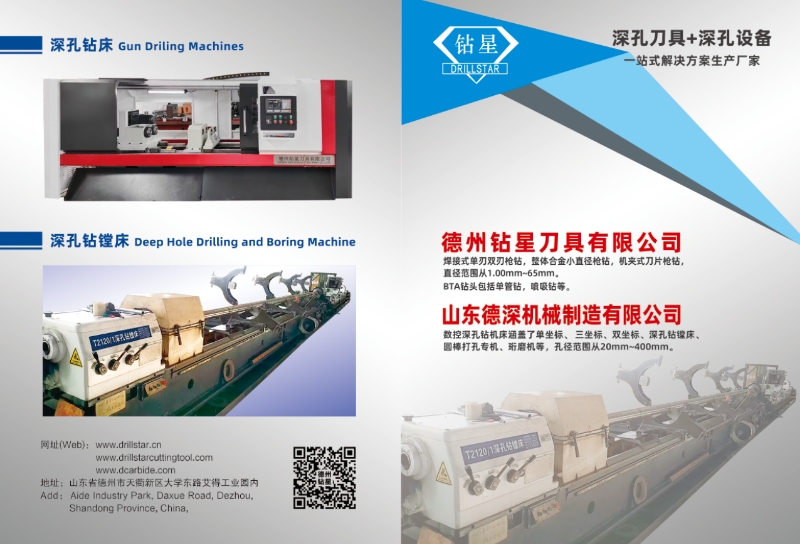

Boring machine

- Features: It has strong rigidity, good accuracy, wide spindle speed range, and the feed system is driven by an AC servo motor. The oil-exporter tightening and workpiece tightening use hydraulic devices, and the instrument displays it, which is safe and reliable.

- Purpose: It is mainly used to process high-precision holes or to complete the finishing of multiple holes at one time. It can also engage in the processing of other processing surfaces related to hole finishing. It is the main equipment for processing large box parts.

Deep hole machine tool

- Features: The precision machining effect can be obtained through one tooling, the machining holes are accurate, the dimensional accuracy is good, the straightness and coaxiality are high, and the surface finish and repeatability are good. It can process various forms of deep holes, which can solve special deep hole processing problems such as cross holes, oblique holes, blind holes and flat bottom blind holes.

- Purpose: It is suitable for processing deep holes with larger length and diameter ratios and is widely used in aerospace, automobile manufacturing, mold industry and other industries.

Reamer

- Features: Usually has high-precision edges, which can accurately control the dimensional accuracy of the hole. The tool material has good wear resistance, which can ensure that it can maintain good processing accuracy after multiple uses. The cutting edge is sharp and the cutting process is smooth, which can effectively reduce the surface roughness of the hole wall.

- Purpose: It is mainly used to further finish the processed holes to improve the dimensional accuracy and surface quality of the holes. It is often used for processing various parts that require high-precision holes, such as engine cylinder blocks, precision molds, etc.

Milling cutter

- Features: The tool material has high hardness, strong wear resistance, and can withstand high-speed cutting and heavy load processing. The geometric design is reasonable, and the shape and angle of the cutting edge can optimize the cutting force distribution, reduce vibration, and improve the quality of the processing surface. The coating technology is advanced, which can reduce friction coefficient and reduce chip adhesion.

- Purpose: widely used in mold manufacturing, mechanical processing and other fields. It can be used in various milling processing such as plane milling, contour milling, cavity milling, etc., and can process workpieces of various shapes and materials.

BTA

- Features: Adopt an internal chip removal design, high-pressure cutting fluid can directly reach the cutting area, quickly discharge chips and cool and lubricate, avoiding chip accumulation and tool overheating and wear. The tool is made of high-quality high-strength alloy material, which has excellent wear resistance and impact resistance after special heat treatment. The tool parameters can be customized, equipped with precision guide devices, and high processing accuracy.

- Purpose: Suitable for processing a variety of materials, including steel, aluminum alloy, stainless steel, titanium alloy, etc. It is widely used in aerospace, automobile manufacturing, energy and other fields, and is especially suitable for processing holes with large diameters and long depths.

We sincerely invite you to visit our booth 53A13 to experience the product charm of Drillstar Tools for yourself, and to discuss face to face with our technical experts how to meet your specific needs with our professional solutions. Drillstar Tools looks forward to meeting you at the Moscow International Machine Tool Exhibition to explore the future of deep hole processing together and open a new chapter of win-win cooperation.